This project involves predicting the diffuse field SPL and reverberation time (RT60) in a performance room and neighboring listening room, given certain characteristics about the performance and the room sizes; and under varying conditions of wall treatment, partition structure, and occupancy. The project is the culmination of a course in Engineering Acoustics, a practical exercise in noise control with real-world features.

Download EEN 502 Project 3.xls

Download original assignment Acoustics Project 3 PDF

Note: I started this project on a computer where MATLAB was unavailable, so I used Excel instead. The correct equations for the computation of loss factor, listening room SPL, etc. are embedded in the worksheet as formulas. I would rather have done this in MATLAB but the charting features of Excel were good enough.

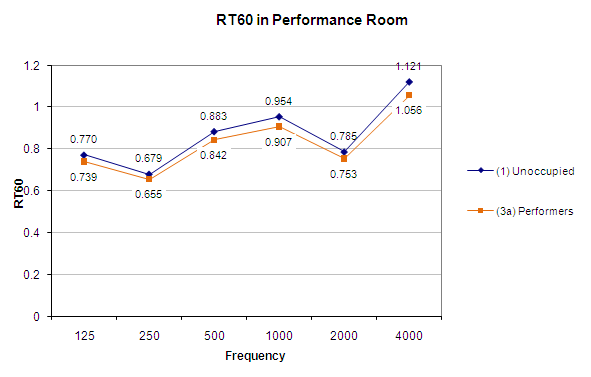

1. RT60 in Unoccupied Performance Room and

3a. RT60 of Performance Room During Rehearsal

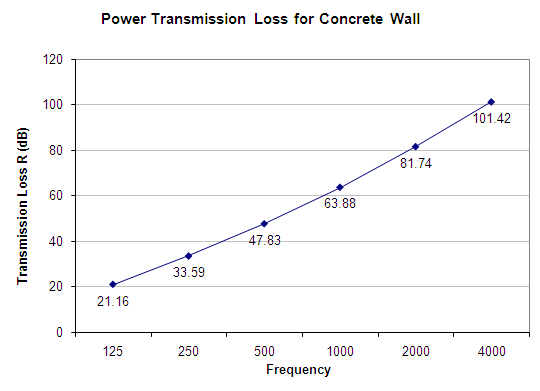

2. Power Transmission Loss for Concrete Wall

Using the formula :

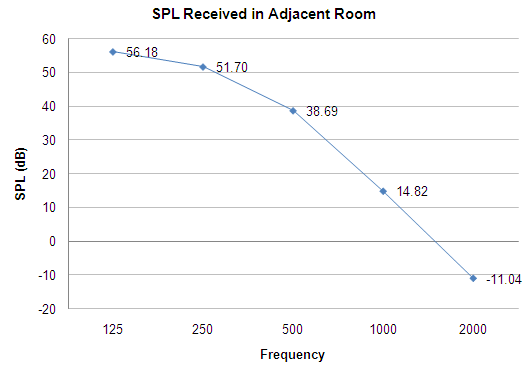

3b. SPL Received in Adjacent Room

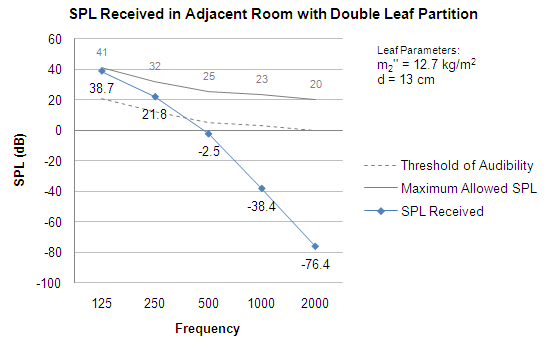

3c. Reducing the SPL in the Adjacent Room

We are faced with the challenge of getting the leaked SPL within 20 dB of the threshold of audibility across all frequencies. The biggest difficulty will be in reducing the lowest frequency band at 125 hz to under 41 dB. The SPL received in the listening room before any acoustic treatment was around 56 dB, so we must find a wall treatment that provides a RE loss factor of 15 dB.

If we double the average absorption coefficient in the listening room, our diffuse SPL only decreases 3 dB - we need more than acoustic paneling. Therefore, I chose to go with a double leaf partition, which means we'll be adding a single barrier at some distance from the existing wall. The flexible barrier surface also works in our favor, as we'll gain a slight attenuation from the new absorption coefficient. In order to attenuate 15 dB at 125 hz, the resonant frequency of the mass-spring created by the airspace and barrier material has to be around 45 hz. This means we need a big mass (heavy wall) and compliant spring (large air gap).

A 5/8" gypsum wall (12.7 kg/m2 density) with a 13 cm air gap provides an additional 15.92 dB attenuation at 125 hz - which is a few dB more than we need, but we will need those extra dB after problem 4b.

Problem 3d is omitted since our attenuation goals were met.

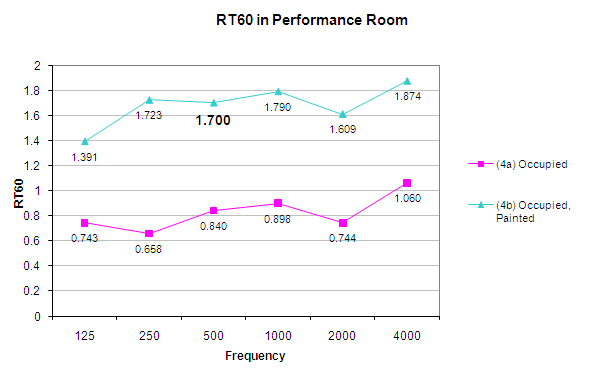

4a. RT60 of Occupied Performance Room and

4b. Achieving RT60 = 1.7s at 500 hz

In order to increase the reverb time of the occupied performance room from 0.84 seconds to 1.7 seconds, we have to make some big changes to the surfaces in the room. The absorption area must be decreased by a factor of 1.7:0.84. The easiest way I saw to do this was to paint exactly 353.7 out of 390 total square meters exposed concrete in the room. (This number includes surface area of the ceiling; the partial painting could be carried out in a number of practical ways.) Painted concrete is extremely reflective compared to unpainted concrete at 500 hz (a = 0.06 vs 0.31).

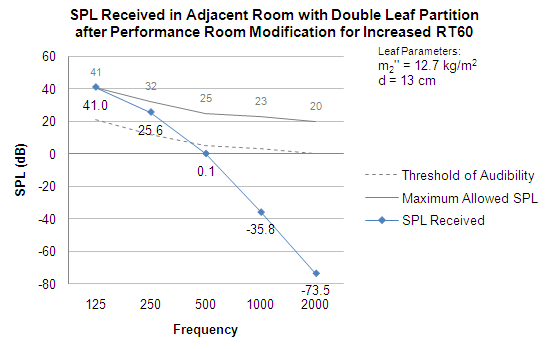

5. SPL Received in Adjacent Room after Performance Room Modification

Increasing the RT60 in the performance has come at a cost; the diffuse SPL in the performance room is higher and thus the SPL leaked to the adjacent room has increased by about 2 to 4 dB depending on the frequency band. For the noise audibility requirement, again, the important band is 125 hz, where our SPL leaked has gone from 56.18 dB to 58.6 dB. As mentioned earlier, our safe margin in problem 3b helps us absorb. After subtracting the loss factor from the double-leaf partition, the SPL received is just inside our threshold for 125 hz, at 41 dB.

Leave a Reply